Newly Developed Taylor Vortex Flow Nano Reactor

Achieves High Shearing Force, High Roundness in a Short Time, Accurate Particle Size

- Uniform Mixing of Gas and Liquid

- Accurate Particle Size Distribution

- Improved Sphericity

- Continuous Production Possible

- Considerable Time Reductions

Use in a Wide Range of Fields Can Be Expected

Fields and Applications

Cosmetics/

Medicine Skin lotions/Creams (stabilization of emulsions, improved texture/feel)

Drug/Delivery/Systems (more efficient transportation of medicinal properties to affected area)

Bulk drug materials (crystallization/precipitation)

Medicine Skin lotions/Creams (stabilization of emulsions, improved texture/feel)

Drug/Delivery/Systems (more efficient transportation of medicinal properties to affected area)

Bulk drug materials (crystallization/precipitation)

Materials for Electric and Electronic Components

Lithium-ion cell materials (higher performance)

Organic electroluminescence emitters (improved dispersibility for increased emission intensity/speed)

Functional resin pigments (improved stability)

Organic electroluminescence emitters (improved dispersibility for increased emission intensity/speed)

Functional resin pigments (improved stability)

Precision Chemistry

CNF (cellulose nanofibers; improved specific strength, isolation)

CNT (carbon nanotubes: improved conductivity)

CNT (carbon nanotubes: improved conductivity)

Food/Beverage

Emulsification (particle size control)

High-functionality food materials (improved substance absorption efficiency in supplements, dairy products, nutritional supplementary food, etc.)

Liquid food (same as above)

High-functionality food materials (improved substance absorption efficiency in supplements, dairy products, nutritional supplementary food, etc.)

Liquid food (same as above)

Petrochemical

Catalyst carriers (high specific surface area/high strength)

Environment

Improved water quality by removal of impurities

Flocculation of solids in waste water treatment

Flocculation of solids in waste water treatment

Application Cases

Gas, liquid and solid is poured into a liquid medium to form Taylor vortex flow. The action of mixing like this promotes a chemical reaction and produces new substance.

-

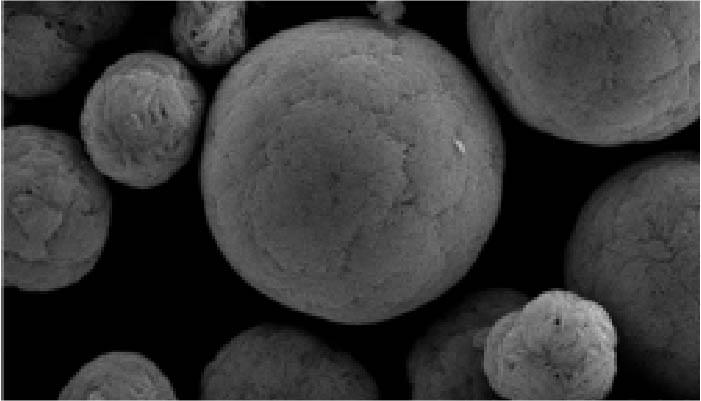

High Sphericity

<chemical materials> SEM images

-

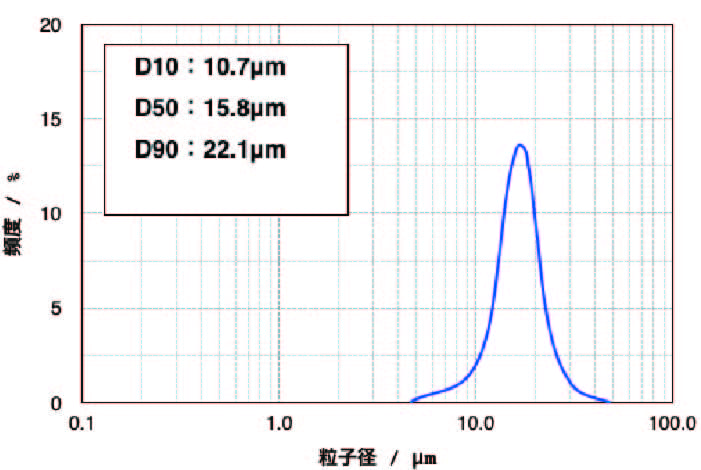

Accurate Particle Size Distribution

Particle size distribution

The particle size is controlled by changing the gap between the inner and outer tubes, number of rotation and flow rate. This enables substance having a small through to a large diameter to be produced.