Come and see our “TVF🄬 Taylor Flow Nano-Reactor” at Interphex Osaka 2023

We will be exhibiting our award winning TVF🄬 at Interphex Osaka (a Pharmaceutical Manufacturing Trade-Show) From Wednesday the 8th until Friday the 10th of March in Pharmira’s booth (No.13-16).

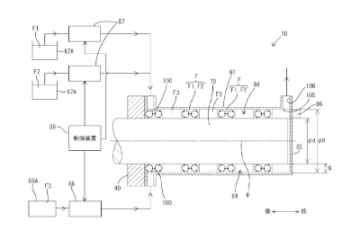

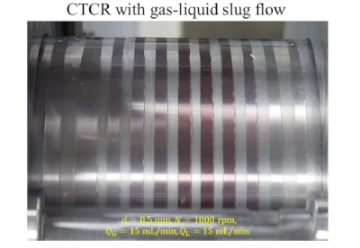

TVF🄬 technology differs from orthodox crystallization methods through its continuously flowing crystallization method. Phamira is currently using TVF🄬 for the production of active pharmaceutical ingredients.

INTERPHEX Osaka 2023 ※Finished

From:March 8(Wed)~10(Fri).2023

Location:INTEX Osaka, Japan

Booth Number:13-16

Click here for more information on Phamira, visit their homepage>